|

If you are using DC motors for antenna movement then you can use an

H-Bridge instead of relays to control the motors.

An H-bridge is a device that controls the speed and

direction of a DC motor, by routing current in opposite directions.

It allows low-power control signals from the controller to drive

higher-power motors. They also

can

use Pulse Width Modulation (PWM)

for speed control, and include diodes to

protect against inductive kickback.

The CT-2 controller will work with certain types of H-Bridges and by

using the jogging feature, true PWM speed control can be realized.

When selecting an H-Bridge to use with the CT-2, several factors need to

be considered:

1. Look for a full bridge device, not a half bridge.

2. If you want to control both azimuth and elevation motors with a

bridge, look at dual H-Bridges. That will simplify the wiring.

3. When using a dual bridge, both motors must be powered from the same

power source.

4. The bridges must be controllable with just two input lines for each

direction (two for up/down and two for CW/CCW).

5. The bridges must stop the motors when both inputs are high as well as

when they are both low.

6. The bridge input lines must be pulled high. If they are not

then use pull-up resistors to assure the lines are high when not being

controlled.

We have tested the CT-2 with three different bridges, detailed below.

One thing to keep in mind is that the bridge must be able to handle the

stall current of your motor. It is a good idea to measure the

stall current yourself so you are sure how much current capacity you

need. |

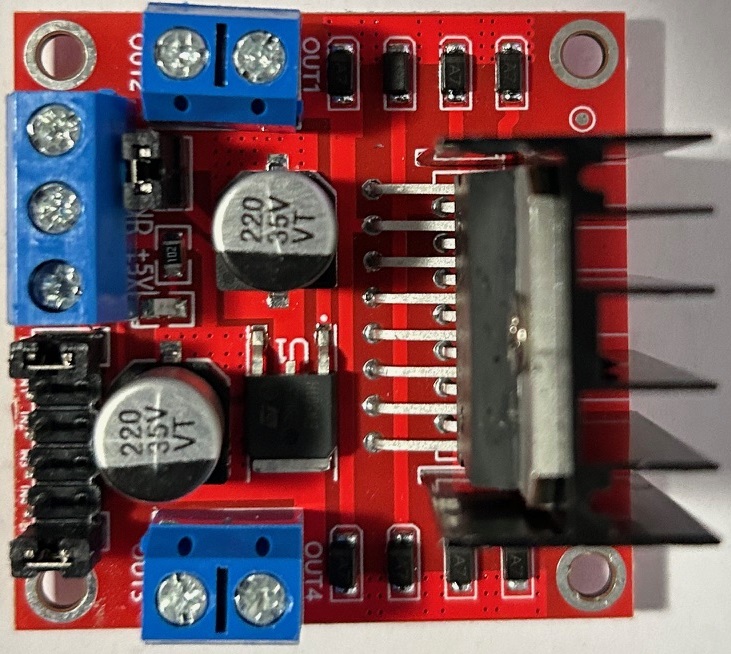

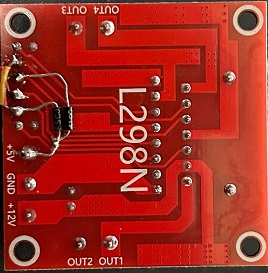

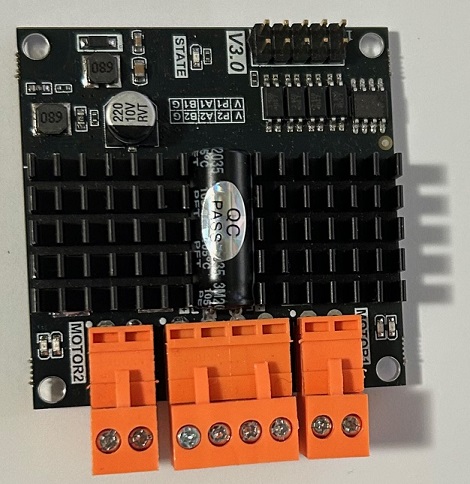

This

is a 7 amp H-Bridge, available from EBay, for about eight dollars. It

is EBay Item 182484648130. It can handle 6.5 to 27 volts at 7 amps.

Price is currently about 7 dollars

This

is a 7 amp H-Bridge, available from EBay, for about eight dollars. It

is EBay Item 182484648130. It can handle 6.5 to 27 volts at 7 amps.

Price is currently about 7 dollars

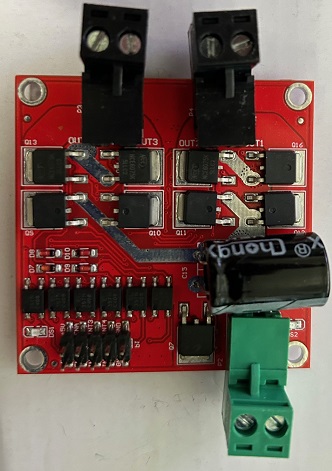

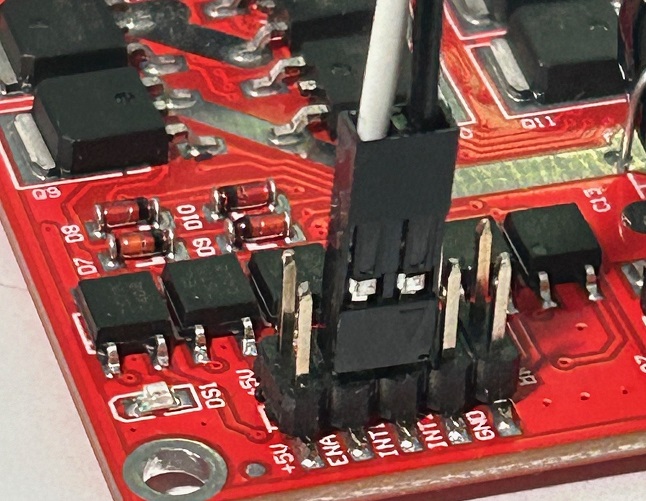

If

you really have a big motor, you can use this 12 amp H-Bridge. It is

available from Digikey for about 29 dollars. Here is the link:

If

you really have a big motor, you can use this 12 amp H-Bridge. It is

available from Digikey for about 29 dollars. Here is the link: